|

Introduction

Nuclear Magnetic Resonance (NMR) has become a useful method for spectroscopic identification thanks to its information about molecule structures and interactions. It is also used in medical imaging. However, compared to other methods, NMR has low sensitivity. Dynamic Nuclear Polarization (DNP) allows this disadvantage to be overcome by transferring the high electron polarization to the nuclei using free radical species grafted on mesoporous materials such as silica powder, with microwaves. For in vivo use, the sample has to be in a liquid state and the paramagnetic species must be filtered, so it is necessary to dissolve and filter the material in the system before recovering an NMR experiment. The aim of this work was to test the dissolving system with different filters and see the efficiency of the filtration on the mesoporous material by NMR analysis. The filter must withstand the system pressure, be very small (maximum diameter 6mm), and filter at least 80% of the material.

Experimental conditions

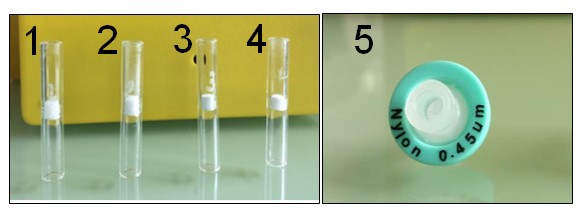

Five filters were tested (figure 1). For each experiment 5 mg of mesoporous material were dissolved in 5 mL of water and filtered under a pressure of 8 bar. A solution named “initial product” was also prepared: 5mg of mesoporous material in 5mL of water. This solution was not filtered. After the experiment, each solution was analyzed by NMR using 400μL of the filtrate and 40 μL of D2O.

Results

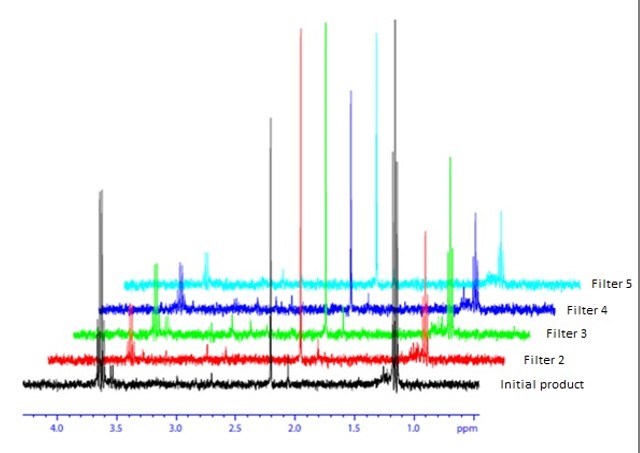

Filter 1 was directly eliminated because a lot of solid passed through the filter. The other solutions were transparent. NMR analysis allowed the efficiency filters to be quantified (figure 2).

The solution “initial product” was considered at 100% of the product. So the peaks at 1.2 ppm and 3.6 ppm were integrated, and those of the initial product were standardized to 100% product. The peak at 2.2 ppm was solvent traces. The integrations of each solutions were compared to the initial product :

Filter 2: integration = 25% of the signal “initial product” so that means that 75% of product was retained by the filter;

Filter 3: integration = 34% of the signal “initial product” so 66% of product retained;

Filter 4: integration = 25% of the signal so 75% retained;

Filter 5: integration = 16% of the signal so 84% retained.

Conclusion

The NMR results proved that filter 5, nylon membrane, seems the most efficient. Besides, it resisted the pressure. However, the diameter was too large, so nylon membrane filter, 0.45μm, 4mm (diameter) has been ordered. They have to be tested to see if they can resist the pressure.

|

|

Figure 1: Filters tested

1) Sintered glass, porosity 100-160μm, diameter 3mm

2) Sintered glass, porosity 40-100 μm, diameter 3mm

3) Sintered glass, porosity 16-40μm, diameter 3mm

4) Sintered glass, porosity 10-16 μm, diameter 3mm

5) Nylon membrane filter, porosity 0.45μm, diameter 13mm

Figure 2: NMR analysis of solutions filtered with each filter (figure1) and the unfiltered solution “initial product” - 400 MHz, in D2O

|