|

Introduction

The plant has received claims from customers concerning excessive oiling of steel coils. Oil application on the steel is important to protect it from corrosion and help customers who canít lubricate the product during stamping. Online, a fixed amount of oil is applied on the strip by gravity at a frequency depending on the line speed. A felt homogenize the oil on the coil. The oil is only applied on one side and the other side is oiled by contact during the coiling. We want to check if the oiling system delivers the right oil quantity for each oiling specification and check the homogeneity on both sides.

Experimental conditions

We measured the oil quantity with Fuchs infralytic device. First, we checked the instrument with manual deposition of oil. We put an accurate mass of oil on a sample and compared it with the reading given by the Fuchs device. As the results were in agreement with the theory, we were able to continue using the FUCHS system.

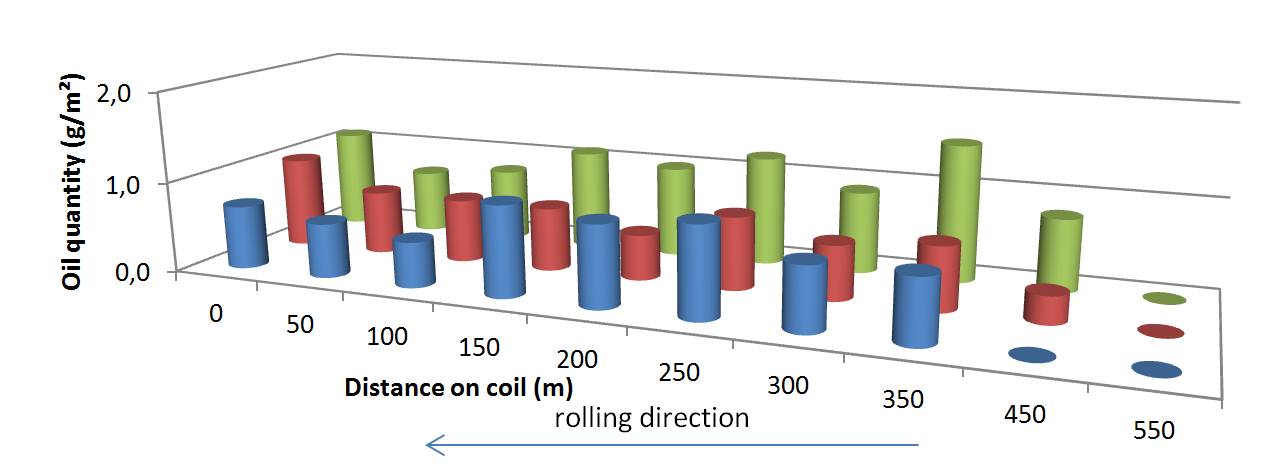

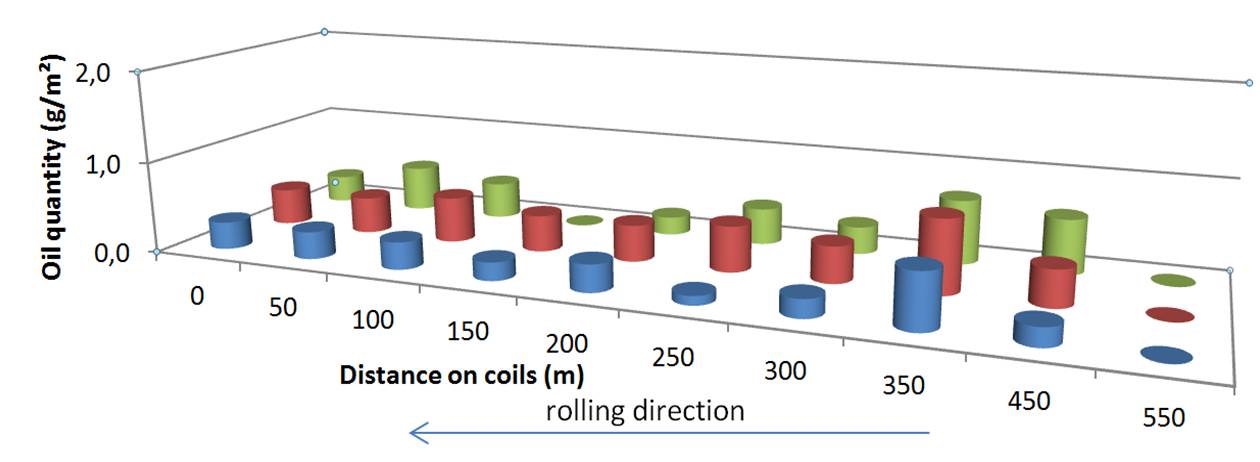

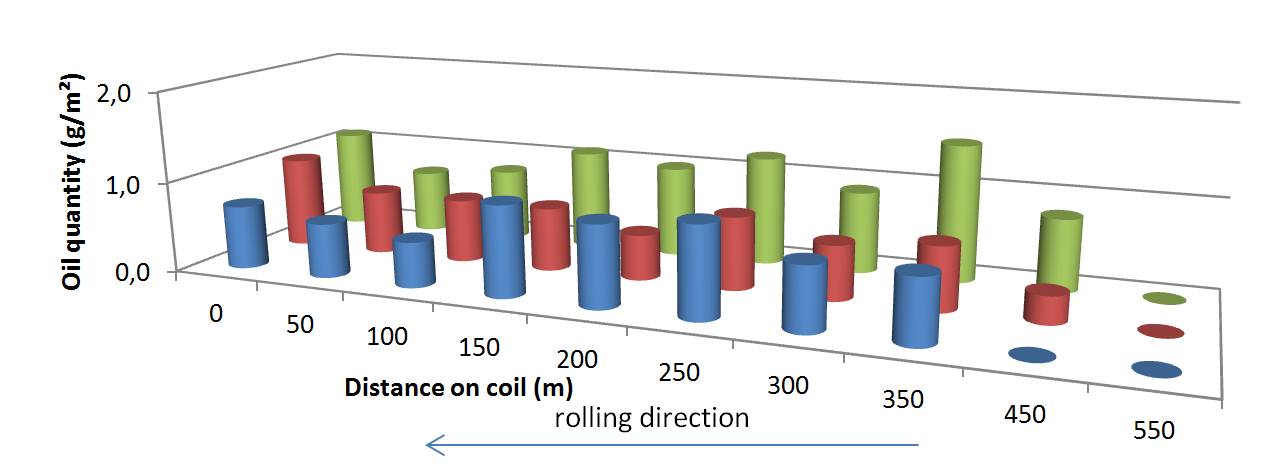

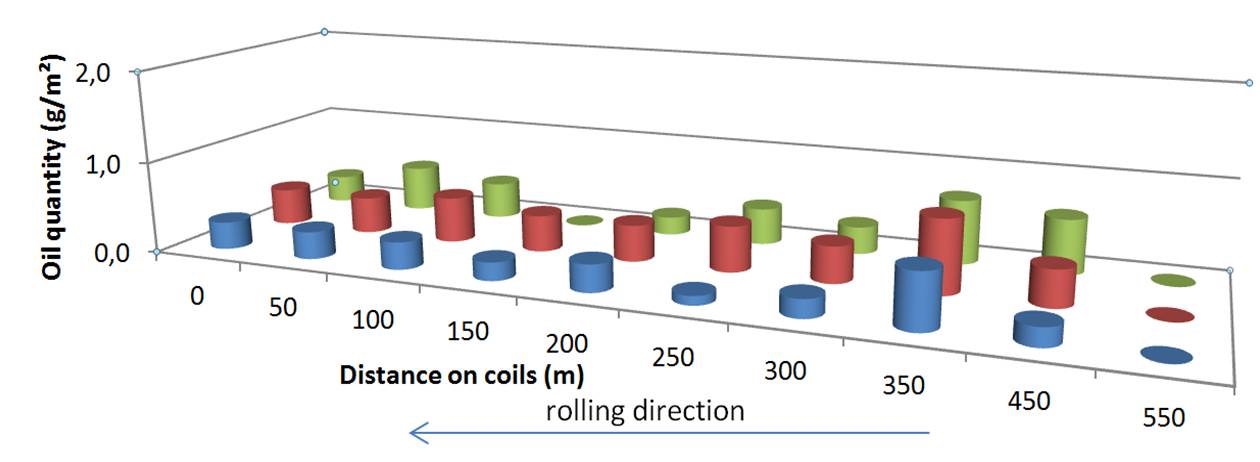

Measurements were processed at the inspection line where we could stop and start the uncoiling easily. Three measurements in the coilís width were processed every 50 to 100 meters. Results are reported on figure 1 and figure 2.

Results

Measurements show that ten injections are necessary to obtain operational oiling system. On the other side of the online oiling, oil quantity was not satisfying because the transfer was too low (fig. 2) and we had lower oil amount compared to the upper side (fig. 1). Considering all our analysis, we have demonstrated that the more oil we put on the coils, the better the transfer is.

Conclusion

To homogenized oil on the support, we could install more felt at the edge of the coil. We suspected that oil heterogeneity was due to the strip waviness and we recommended to install more flexible arms on the edges of coil for a better the oil application.

|

|

Measure oil quantity on the superior side

Measure oil quantity on the inferior side

|