|

Introduction

Porcher Industries is a company which creates technical textiles. There are many applications in automobile, electronic, sport and industries. Each application has its specific fabric which is controlled and validated by the laboratory where there are different tests. For example, to measure the width of the fabric, its thickness, the weight per square meter, the loss of ignition (to determinate the percentage of organic matter in the fabric), the tensile strength and the tear strength. The last test consists in evaluation the force required to tear specific fiberglass fabrics named “tissu écru” used for electrical insulation. This test is complexe to make because the test method is not reliable and there is a big standard deviation between different measurements. My objective was to develop the test method of the tear strength to make it more reliable. To be validated, values had to be superior or equal to 5.30 kg/cm.

Experimental conditions

Dynamometer INSTROM, pattern, cutters, rulers, glass glue and fabrics “tissu écru” with the same yarns were used.

Sample preparation: cut fabrics and stuck it on the patron paper with the glue glass. Created 8 samples per set and 40 for each parameter to test. Waited 10 minutes and cut samples. Notched each sample in its center at 20 mm with a ruler and a cutter. Waited between 5 and 96 hours minimum (study 2) before the second part.

Configuration of the dynamometer: calibrated it then do the standardization with specifics plastics samples.

Configuration of the software named “O-QIS”: the width of the fabric (170mm), the notch width (20 mm) and the number of samples per set (8).

Realization of the test: inserted sample in jaw of dynamometer. Applied a preload and started the test of the tear strength. When the sample is broken, the dynamometer automatically stopped the test. Results were present on computer in the software O-QIS.

Results

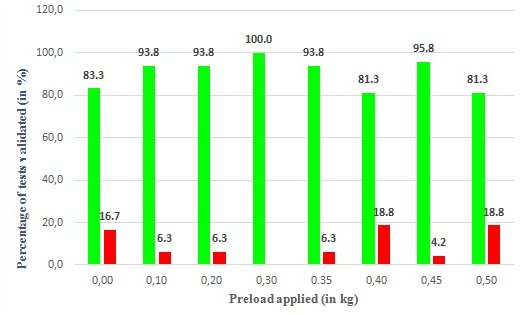

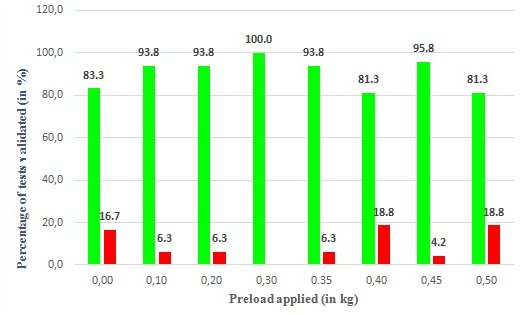

Fig. 1: When a preload of 0.30 kg was applicated, every sample were validated (superior to 5.3 kg/cm). When a preload of 0.00 ; 0.40 or 0.50 kg was applicated, results were bad.

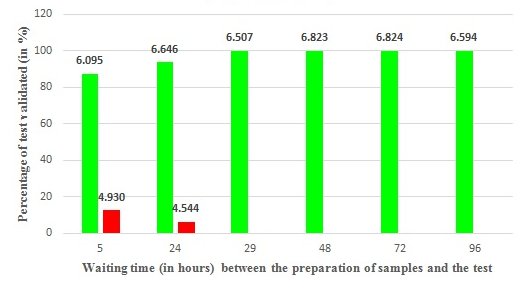

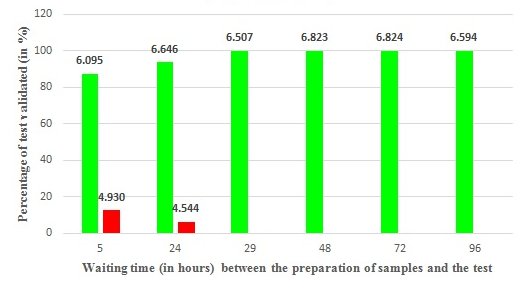

Fig. 2: When there were more 29 hours between the preparation and the test, 100 % of correct results were obtained. Furthermore, when there were between 48 hours and 72 hours between the preparation and the test, better values were obtained (6.823 and 6.824 kg/cm).

Conclusion

In theory, results must be superior to 5.3 kg/cm. The major part of my results is superior to 5.3 kg/cm. But, for this study, I used the fabric named “ecru” with the same yarns. To deal with this study in depth, I had to study fabrics named “ecru” with different yarns.

To carry out the test of the tear strength with the specific fabric named « tissu écru », we must apply three parameters. First, samples must be notched at 20 mm. Second, we must wait 48 hours minimum between the preparation and the test. Third, we must apply a preload of 0.30 kg.

|

|

Fig. 1 : Percentage of tests validated in function of the preload applied (in kg) for the fabric "tissu écru"

Fig. 2 : Percentage of tests validated in function of waiting time (in hours) for the fabric "tissu écru" with average values on the top of picks (in kg/cm)

|