|

Introduction

The purpose of this study is to examine the influence of fire on refractive index values of glass fragments. During a car theft, the suspect possibly set fire to vehicule to delete crime evidences. We suppose a change in refractive index of glass fragments that have been subjected to a fire. So the comparison with the fragments recovered from the suspect (clothes, hair,...) wouldn’t be discriminant. For our experiment, cars have been subjected to fire and a set of glass fragments has been collected before and after the fire. The refractive index values are determined by thermoimmersion method with the use of GRIM 2 instrument, specially designed for forensic glass examination. Then, we examine if an annealing procedure (Locke’s procedure) could be used to overcome the supposed change in refractive index, caused by a fire.

Experimental conditions

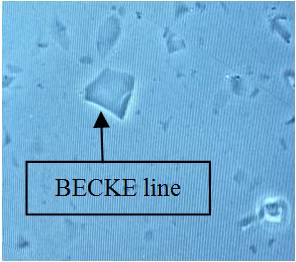

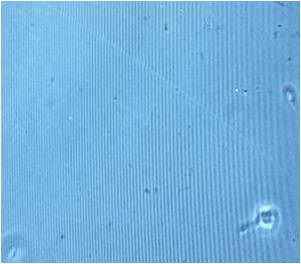

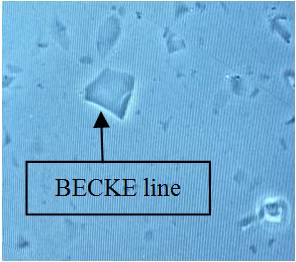

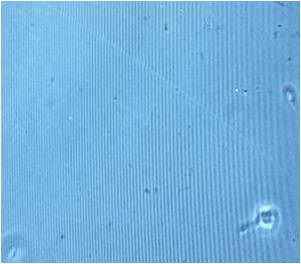

For the method of the BECKE line, glass particles are immersed in phase contrast microscope, illuminated with monochromatic light. As the refractive index of oil depend on temperature RI=f(T), with a hot-stage oil temperature is increased until the glass fragment and oil have the same RI. At this point, the match temperature, the glass fragment cannot been distinguished (Figure 1, Figure 2). This allows us to determine refractive index of the analysed glass.

At first, all samples were analysed and the refractive index of both burned and unbuned glass fragments were measured, then they were annealed in the oven to overcome the undergone disturbances. The cycle of annealing procedure lasts approximately 22 hours. It begins with fast rise in temperature (560°C), the temperature is held at 560°C for 2 hours, followed by a slow cooling period (15 hours) when the temperature is decreasing down to a temperature of 500°C, before the oven is allowed to cool down to room temperature.

Results

The results obtained during this study are average results. To consider that refractive index at two fragments are similar, the difference between both (ΔRI) is lower 1,00E-04. At first, fragments resulting from two vehicles were analyzed without being annealed. Refractive index of unburned fragments was compared with refractive index of burned fragments. It was noticed that all ΔRI were higher than 1,00E-04. Refractive indexes are different, which means that the fire has an incidence on the value of refractive index. Then samples were once annealed, which allowed to obtain ΔRI lower than 1,00E-04. To try to obtain RI lower than 1,00E-04 for more fragments ; samples were annealed a second time.

This allowed a sample to have ΔRI lower than 1,00E-04, and the other values evolved little. Analyses thus stopped later two annealing procedures. To see if two annealing procedures allow a majority of fragments to overcome disturbances having been undergone, the fragments of another vehicle were directly twice annealed, then analyzed. The ΔRI of all fragments were lower than 1,00E-04. It confirmed that two annealing procedures are enough.

Conclusion

Therefore, fire as in incidence on the value of RI. The study shows that Locke’s annealing procedure (2 cycles) can be used to overcome the variation in refractive index values caused by high temperature as fire and allows the possibility to compare the refractive index of glass fragments subjected and not subjected to a fire.

However, some strongly deformed samples, have different refractive index values even after 2 cycles of annealing procedure.

It is thus possible that they underwent more disturbances than others. For these samples, Locke’s annealing procedure is not efficient, so a method based on quantitative elemental analysis by LA-ICP-MS should be performed.

|

|

Not at "Match Temperature" (we see particle of glass)

At "Match Temperature" (we don’t see particle of glass)

|