|

Introduction

Analysis of elements in pigments for oil painting is essential for different applications. Knowing the contents of the materials used can help to understand the situation of the artwork for conservation and restoration. It can also provide information to study the culture in the past and the history of the pigments manufacturing processes. Different kinds of spectroscopy techniques are applied in this field. This project will demonstrate the pigment analysis by using laser-induced breakdown spectroscopy (LIBS).

Experimental conditions

A standard setup of laser-induced breakdown spectroscopy (LIBS) was used. The focused laser was applied as an excitation source to ablate the sample and produce a plasma plume. This atomized and excited the samples. The ablation source was a Q-switched Nd:YAG laser operating at 1064 nm with repetition rate of 10 Hz. A laser fluence of 180 J/cm2 was delivered to the sample with a crater diameter of about 250 μm. The captured plasma emission was focused and transmitted into an echelle spectrometer equipped with an ICCD camera (Mechelle and iStar from Andor Technology). A series of samples including reference samples (Fe2O3 powder, ZnO powder and TiO2 powder), validation samples and unknown samples (pigments and paints) were analyzed. All the emission spectra were recorded by 200 shots accumulations with 8 replications. Each spectrum was recorded with an optimization of 2 μs delay and a detection gate width of 3 μs.

Results

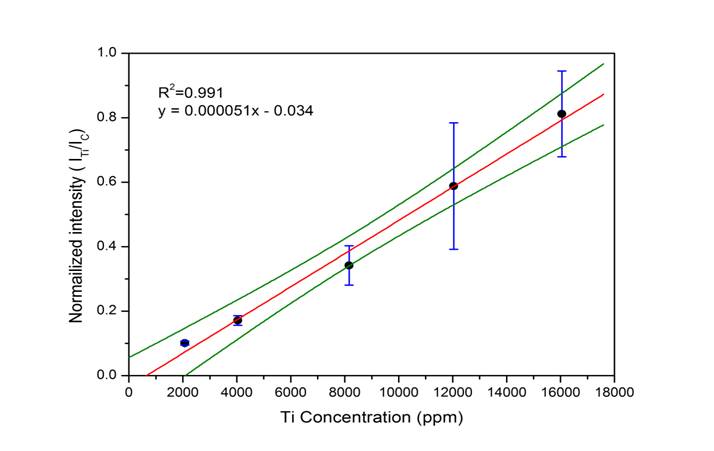

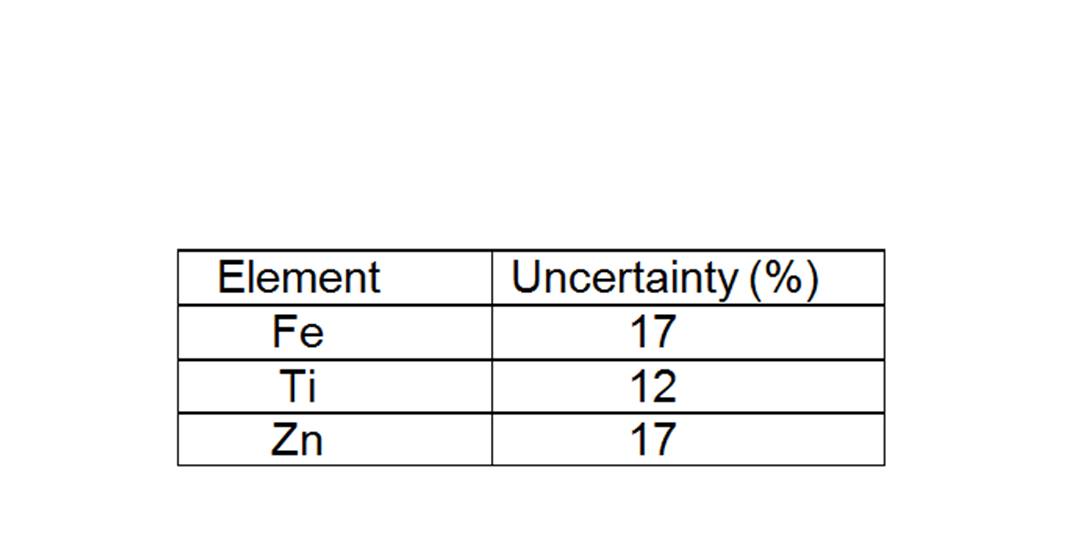

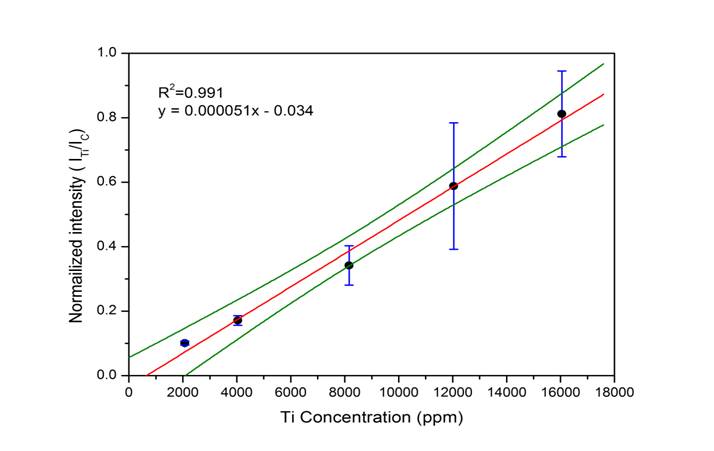

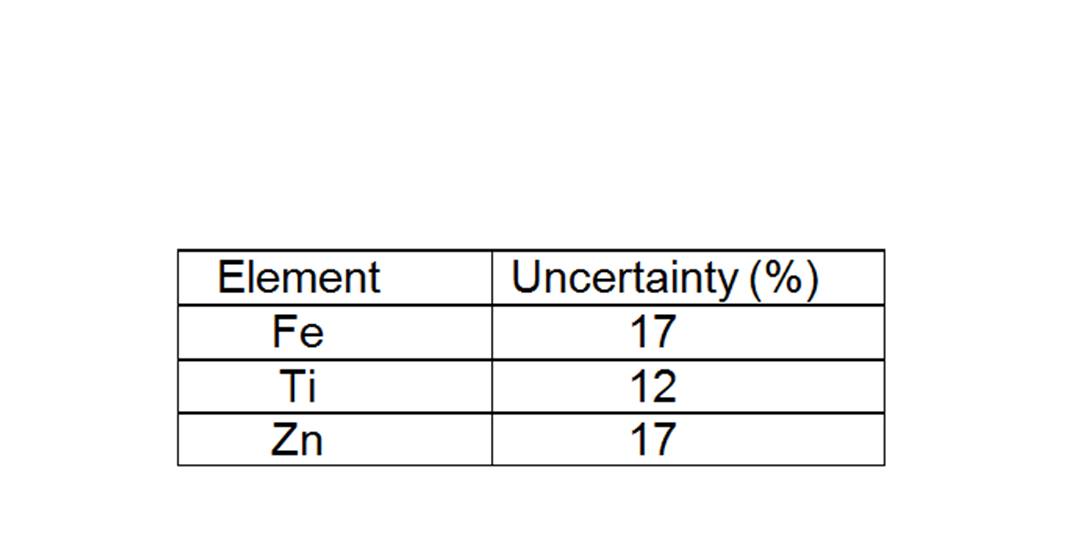

Emission spectra were analyzed with the help of peak detection software to determine the presence of elements. By using the data of the 3 reference samples, 3 calibration curves for Fe, Zn and Ti were obtained with determination coefficients, R2 in the range of 0.983 to 0.991. They were validated by different samples with known Fe, Zn and Ti concentrations. The minimum errors of the calculated concentration to the real concentration in Fe, Zn and Ti calibration curves were 2.67%, 6.16% and 2.54%. Using the calibration curves, the concentrations of Fe, Zn and Ti inside the 5 unknown samples including 3 pigments and 2 paints were then determined.

Conclusion

Analysis of microparticle powder samples in dispersed oil with LIBS is efficient and convenience. Normalization helps to reduce fluctuation and improve the linearity. The convincing results from the validation proved the experiments, setup and sample preparations were carried out properly. This method will keep developing to improve the sensitivity and accuracy.

|

|

The calibration curve of the element Ti with R2 equals to 0.99.

The uncertainties of the validation result for 3 elements.

|