|

Introduction

The plastic’s formulation is different by the characteristics that film can have. Wording is composed of polyethylene and different additives. UV-stabiliser are important to protect films used in agriculture. They have the specificity to limit harmful actions from UV on polyolefin resins. UV-stabiliser contain molecules such as Chimassorb 944 and Tinuvin 622. These molecules are HALS (hindered amine light stabilizer). To produce efficient products, it is important to control the quantity of these additives in the formulation. The purpose of this study is to compare the UV-stabiliser rates between two samples of master-batch raw material which have a different appearance to avoid producing an improper plastic.

Experimental conditions

These two samples have been chosen because they don't have the same color. One sample is yellow and the other one is white. The analysis is done by infrared spectroscopy Perking Elmer Spectrum 100. The method of measurement is carried out from a reference peak. The reference peak is a characteristic peak of polyethylene at 2020cm-1. Working with a peak ratio alleviates the thickness variations of the sample according to Beer-Lambert’s Law. The measurement is performed on the characteristic peaks of Tinuvin 622 at 1730cm-1 (corresponding to chemical function ketone) and at 1000 cm-1 (corresponding to ester), Chimassorb 944 at 1530 cm-1 and at 810 cm-1 (corresponding Triazine cycle).

The sample preparation is carried out by pressing the material at 200 bar and 160 °C. Samples are homogenized 5 times. Analyses were performed on 3 different areas of 80µm. Results are calculated from the average of the three studied areas.

Results

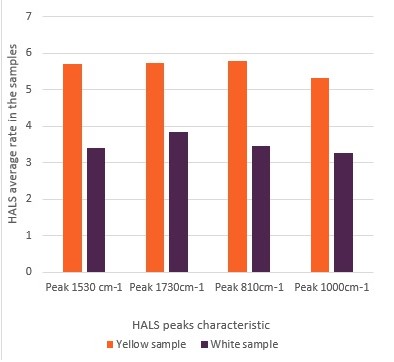

Graphic 1 represents the average HALS rate (molecules having anti-UV properties) of both samples. The white sample contains 3.43% (mean of measures on 1530 and 810cm-1 peaks) of Chimasorb944 and 3.56% (mean of measures based on 1730 and 1000cm-1 peaks) of Tinuvin 622. The yellow sample contains 5.75% (mean of measures on 1530 and 810cm-1 peaks) of Chimasorb944 and 5.52% (mean of measures based on 1730 and 1000cm-1 peaks) of Tinuvin 622. The white sample is below specifications for both Chimasorb 944 and Tinuvin 622 (5% of each specified).

Conclusion

The white sample can’t be accepted for the manufacture plastics for agriculture. The rate of HALS is too low to ensure a consistent product. Only formulations containing HALS rates of 5% will be used for the manufacturing of UV-stabilized films.

|