|

Introduction

Cement is an elaborate commodity but with a fairly low selling price. Thatís why the cement industry has to optimize its manufacturing process. It is a very energy consuming process especially during grinding operations and heat treatment.

In addition to mechanical actions on facilities to improve the energy efficiency of grindings, other processes are implemented and consist in adding products called grinding aids to the material during the grinding step.

Experimental conditions

Two types of analyses were carried out, in order to estimate the effect of the grinding aid: measurements of the particle size and the Blaine Specific Surface test after different numbers of mill turns.

Malvern laser granulometer MS3000 and Micromeritics Blainemetre were used to perform these analyzes.

Before entering in the grinding step, material must be crushed in a first step to a size less than 3.15 mm up to get a more regular grinding step. The crushed material is then ground with the help of calibrated balls, until the expected particle size is obtained.

Here, a dicarboxylic acid was tested as a grinding aid at three different dosages.

The reference is corresponding to the industrial cement. So we are trying to get closer to its specifications.

Laser granulometry allows the measurement of particle sizes, it is a method based on the light diffraction and mathematical calculation.

The Blaine test, called also air permeability, is a method of measuring the cement fineness, which gives a measure expressed in terms of specific surface area (in cm2 / g), i.e. the developed area per unit of mass. This method consists in measuring the time taken by a given volume of air to go through a sample.

Results

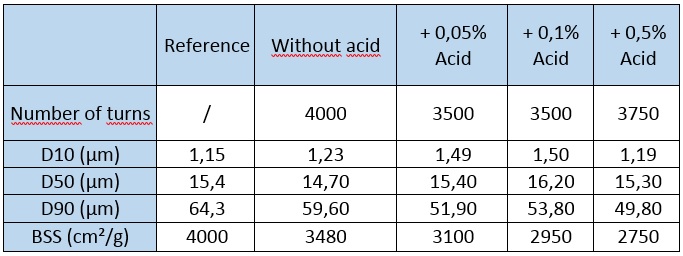

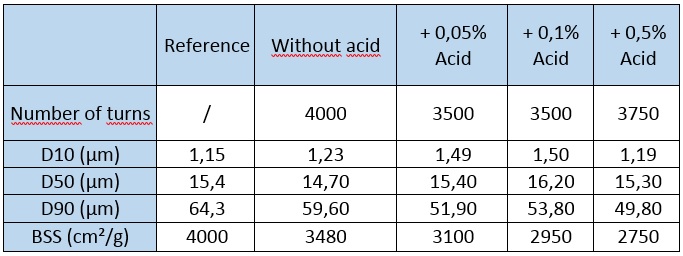

Three parameters were compared to determine the effect of the added additive:

- Number of turns,

- D10, D50 and D90: 10%, 50% and 90% of the sample was less than X micrometer,

- BSS (cm2/g).

We can see in Table 1 that the addition of acid reduced the number of turns to reach the desired D50. However, if the dosage is too high, we had to do more grinding turns.

Also, as shown in the table, the higher the dosage, the lower the BSS.

Conclusion

So, the additive has an impact on the grinding efficiency of clinker. Indeed, it reduces the number of grinding turns. But if the dosage is too high, the efficiency is lower, it is necessary to find an optimum dosage. There is also a significant decrease in the specific surface area when the grinding aid amount is increased. This could be explained by other types of analyzes, such as surface analysis of powders with Zetameter and Dynamic Vapor Sorption.

|

|

Table 1: Results for reference and additive.

|