|

Introduction

Nowadays, nuclear power plant is known as an energy technology which can produce large amounts of energy at a reasonable cost without releasing greenhouse gases. The study of the behavior of gaseous fission products such as xenon in coating materials is essential to ensure the safety of the nuclear reactor (control the leakage of the radioisotopes).

Silicon carbide (SiC) is one of the coating materials that could be used in future nuclear reactor (GEN IV) due to its high melting temperature (over 2500°C), good mechanical property and very high resistance to irradiation.

In this study, polycrystalline samples of SiC are implanted in xenon 129 at fluence of 10^16 at/cm^2 at room temperature and at 500°C.

Experimental conditions

The implantation was carried out using the ionic implanter 400 kV IMIO 400 of IPNL Laboratory (Institut de Physique Nucléaire de Lyon).

After irradiation, the surface morphology is observed under SEM (Scanning electron microscope) in the secondary electrons detection mode. This work is conducted by the Zeiss Merlin compact SEM in the CTµ (Centre Technologique des Microstructures de Lyon) in Lyon.

Results

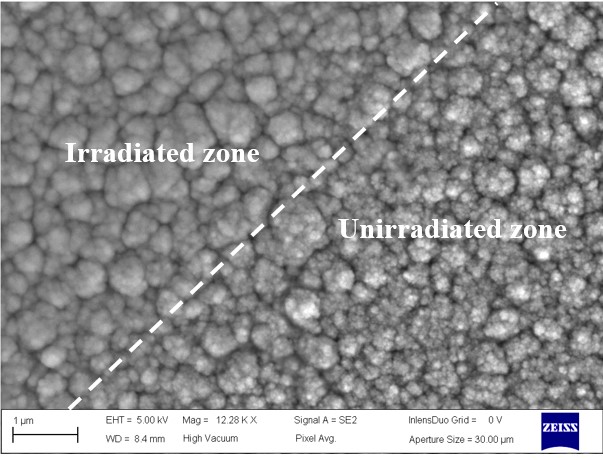

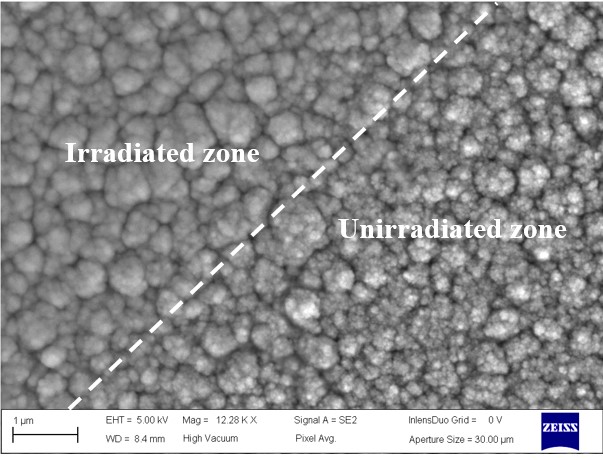

The surface morphology of the polycrystalline SiC is visibly modified after implantation at the dose of 1x10^16 at/cm^2 at room temperature. Comparing with the surface of the non-irradiated zone that is rougher, the surface of the irradiated zone shows smoother and wider nucleuses. This difference is attributed to the probable amorphization of the material in these irradiation conditions.

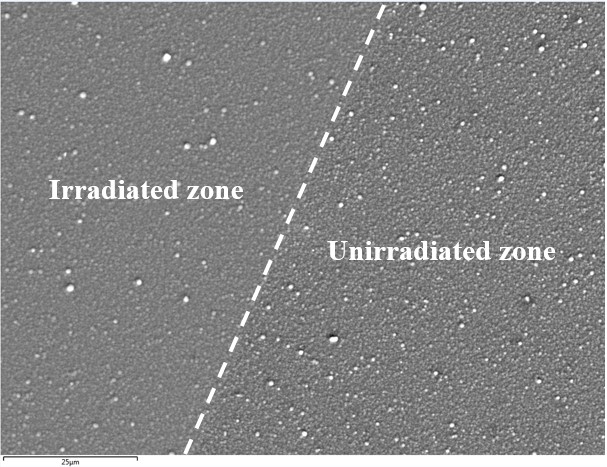

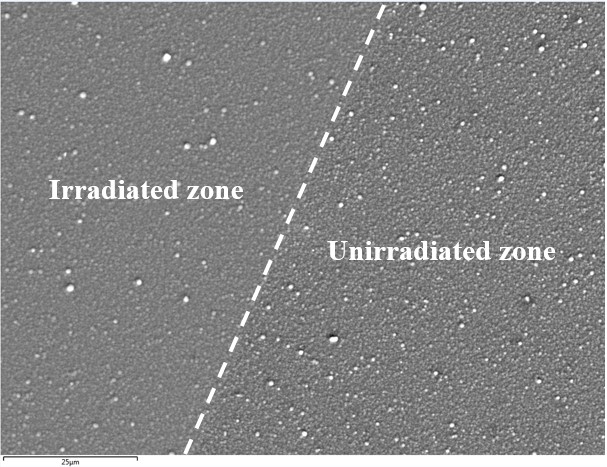

On the other hand, there is no remarkable difference before and after irradiation at 500 °C. This observation is probably due to the fact that implantation temperature exceeds the critical amorphization temperature (about 200 °C), thus structure is preserved. Surface composition is modified by xenon irradiation as oxygen uptake was measured. This oxidation is more pronounced for polycrystalline SiC after irradiation treatment at 500°C (vs RT). Finally, the retention of xenon seems more important during irradiation at room temperature. This phenomenon may come from the mobility of interstitial that augments with increasing temperature.

Conclusion

SEM allows us to analyze the surface of the samples with a much higher resolution. In the future, the sample will be analyzed under TEM (Transmission Electronic Microscopy) to confirm the microstructure and under IBA (Ion beam Analysis) to quantify the chemical compositions present in the poly SiC before and after irradiation.

|

|

SEM image of the boundary between the unirradiated and irradiated zones of the Polycrystalline samples at room temperature

SEM image of the boundary between the unirradiated and irradiated zones of the Polycrystalline samples at 500°C

|