|

Introduction

Numerous aluminum alloys exist and differ in composition or in the elements they contain. This composition can be determined thanks to inductively coupled plasma ICP-OES because it has the advantage to be a multi-element simultaneous method. It requires to work with a solution sample, which is why a chemical attack is necessary for our solid alloys.

A traditional chemical attack with hydrochloric acid and nitric acid may be sufficient for many alloys but not for the high-silicon alloys that we wish to analyze here. Indeed, silicon is a difficult element to mineralize.

In this article, the aim of the experiments is to bring out the chemical attack for a 11%-silicon aluminum alloy in order to analyze it by ICP-OES.

Experimental conditions

Chemical attack, before ICP-OES analysis, was performed on a heating plate at 200°C ± 50°C, on a mass of 500 mg of sample. It began with an attack using 10 mL of soda, and, after, with 3 mL- hydrogen peroxide addition until reaching syrupy consistency. Then, 20 mL of ultrapure water were added and heated to a boil. The attack finished by simultaneous addition of 10 mL-hydrochloric acid and 10 mL-nitric acid. Then, the mixture was put into a 250mL flask.

In order to validate this experimental protocol, a 11% silicon- reference material was used as a sample, to validate the chemical attack.

This silicon high-proportion required a dilution by 10. Therefore, 10 mL of the previous solution (250 mL-flask) were pipetted in a 100 mL-flask. Finally, 5 mL of lanthanum, an internal standard, were added.

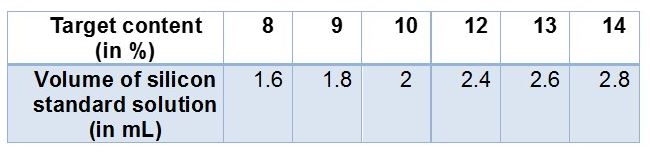

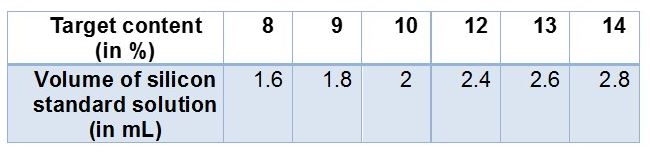

A calibration range was performed similarly, using 500 mg of high purity aluminum (>99.9%), in order to reproduce the matrix. Then, variable volumes of silicon standard solution were added, as illustrated in Table n°1 below.

Calibration range and reference material are analyzed on Thermofischer spectrometer.

Thermofisher parameters :

Speed peristaltic pump : 50 revolutions per minute

Auxiliary gas flow : 0.5 liter per minute

Nebulization gas flow : 0.55 liter per minute

Cooling gas flow : 12 liters per minute

Wavelength silicon : 251 nm

Results

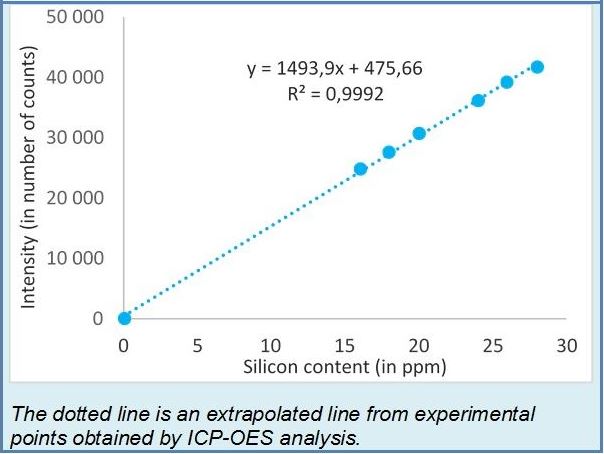

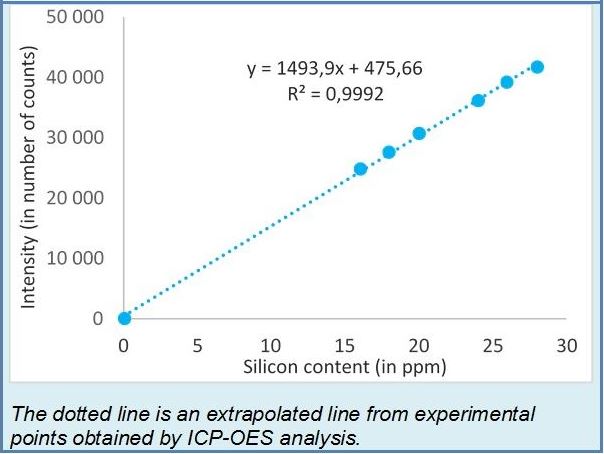

After ICP-OES analysis, the calibration curve, attached in Figure n°1 below, was obtained. The correlation coefficient is over 99.9%, which proves that intensity and silicon content have a sufficient linearity.

In this way, the calibration curve could be used to find the silicon composition of the reference material. Thanks to the silicon intensity obtained at 251 nm, it is possible to calculate its composition. This is done by reporting the given intensity on the calibration curve. We must be careful to consider the correction factor, due to weighing and to dilution:

(Final volume before dilution (in liters)*Dilution factor)/(Mass of the test sample (in grams))

The analysis for the reference material resulted in a silicon content of (11.06 ± 0.20)% for the reference material ; and this one was included in the interval given in the analysis certificate.

Conclusion

To conclude, chemical attack method with soda, hydrogen peroxide and acids allows to dissolve all the alloy, without any loss, even if it contains 11% silicon. In this way, the silicon content obtained by ICP-OES is compliant with the true composition, mentioned on the certificate (10,82% - 11,22%).

|

|

Table n°1 : Target composition of silicon and volumes of standard solution

Figure n°1 : Silicon calibration curve obtained after ICP-OES analysis of six standards for aluminum alloy analysis at 251 nm.

|