|

Introduction

The combustion analysis is a key process of several industrial area such as the glass industry. These analysis involve several issues in particular environmental problem with pollutant emissions and economic with the fuel consumption.

For the purpose of optimizing the combustion, we get the amount of oxygen and unburnt compounds present in the flue gases. In this way, itís important to get a representative, relevant and homogeneous sample. This method has for goal to check the sampling.

Experimental conditions

We tested a systemís sampling which is used in the glass industry. In order to validate the systemís sampling, we got the response time of the sensor. We compared the response time of 2 sensors. The first one is a portable sensor with electro-chemical cell, named Testo 330-1LL, another one made by Rb technologies with a oxide zirconium sensor named ZPF2 (Zircon Probe Fuji 2).

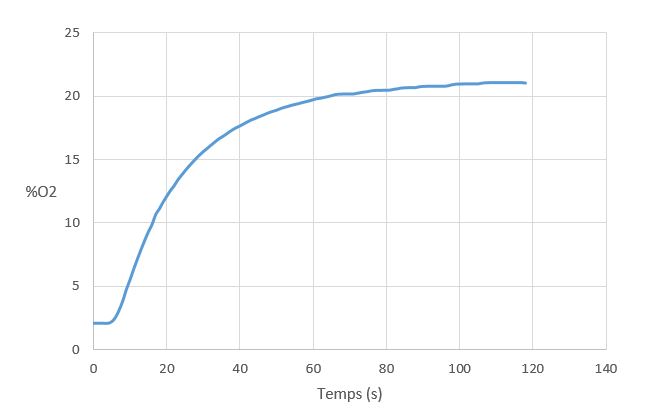

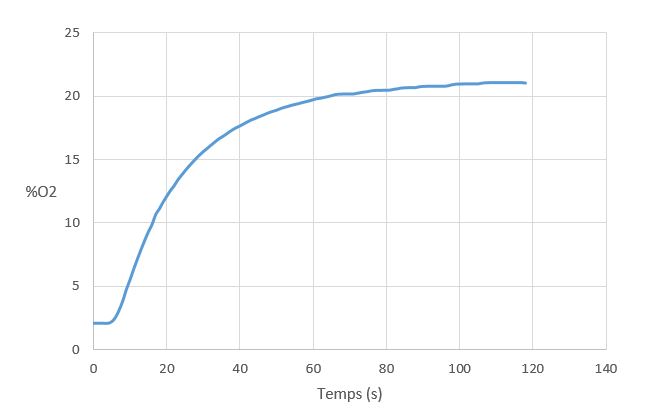

To measure the response time we put a standard gas 2% Oxygen and 300 ppm monoxide carbon, but the testo coundnít be calibrate so we used only the oxygen to make the measure. At the beginning of the test we put the gas until the measure reach 2% and stay stable, then we stopped the gas and recorded the cinetics as we see in the picture 2. With the cinetics we could deduce t90 and t60 wich coresponds to the time ŗ 60 and 90% of the variation.

10 series of record were made with the ZPF2 and only 5 with the Testo because of the difficulty to record the measure, we couldnít sometimes get enough point to make a cinetics. A last test was made with a naked sensor.

Results

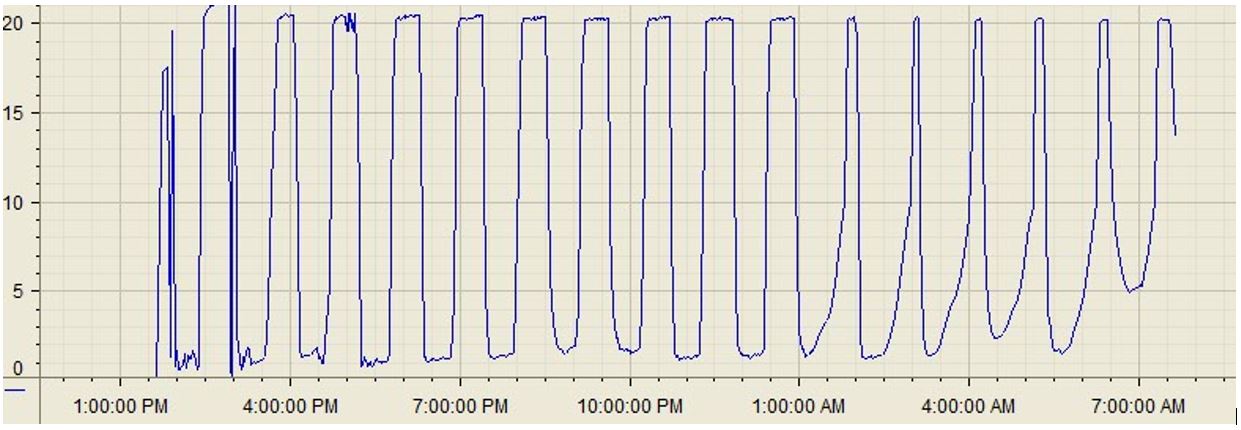

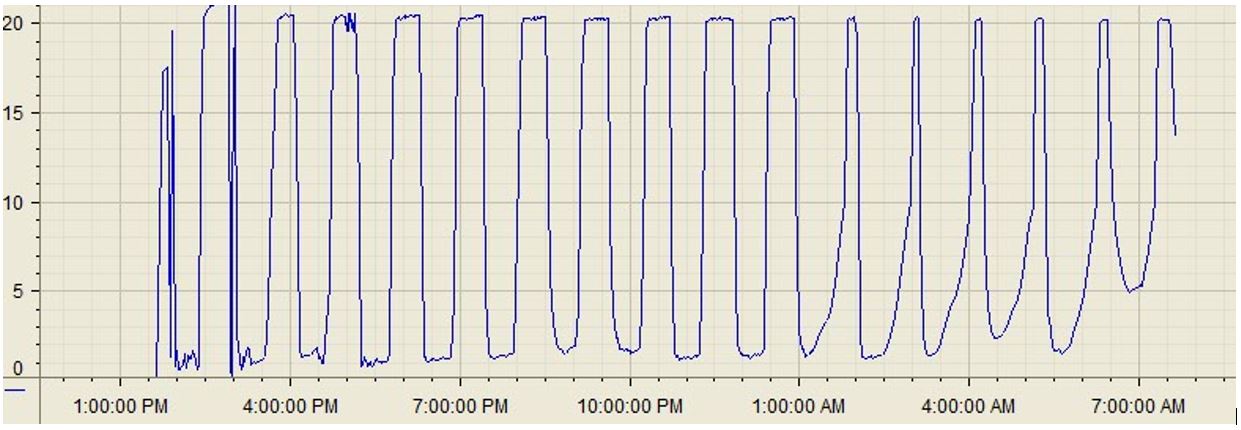

The method will be use to detect sampling problem, for example when the pump of the system stop working, the gas will stagnate into the ceramic tube therefore the response time of the sensor will be affected as we see in the picture 2. The ZPF2 was used as a reference because the test will be use on-site to validate the sampling. All of the sensor had low responses times.The Testo had lower responses times than the ZPF2 but near to the naked sensor. So the protection of the ZPF2 affect the response time, the protection slowed the gas access. The Testo could be used to validate the smoke sampling

Conclusion

The Testo had responses times near to the 2 others sensors. So the portable sensor could be use to validate the smoke sampling despite difficulties to record the data,

|

|

line graph showing the percentage of oxygen as function of time in the method

line graph showing the percentage of oxygen as function of time in the oven

|